The Risk of Silica Dust – Knowing your Responsibilities in prevention

As you know, Authorities are cracking down on Health and Safety concerns within the stone industry relating to exposure to Silica Dust which can be fatal over a period of time and can lead to illnesses such as Silicosis and even Lung Cancer.

Excessive exposure to airborne silica dust can happen in activities such as:

- Cutting and working with stone (especially reconstituted stone surfaces).

- Angle grinding and polishing stone.

- Cleaning up of dust and debris created by the above activities.

Stonemason’s exposure to crystalline silica dust is particularly high. Below you can see the breakdown of the percentages based on common stone products and their typical silica content. Most modern stone benchtop makers work mainly with reconstituted stones which contain more than 90% crystalline silica dust content!

Data as per WorkSafe Victoria A Health and Safety Solution 2017

“Silica is classified as a hazardous substance and is therefore regulated under Chapter 4 – Hazardous Substances – of the 2017 Occupational Health and Safety Regulations Australia. This means that the employer has the legal duty to ensure a safe work environment such as to identify the hazard and eliminate or control any risk, provide information and training, undertake atmospheric monitoring, maintain records and carry out health surveillance”.

Sources of information can be found at : http://www.legislation.vic.gov.au/Domino/Web_Notes/LDMS/PubStatbook.nsf/b05145073fa2a882ca256da4001bc4e7/05C39981B52D9E0FCA25810E0021D052/$FILE/17-022sra%20authorised.pdf

Solution to the problem?

A while back we introduced you to our MH30 Wet Wall Dust Collector. Due to popular demand, we have expanded the MH-Series to include a range of sizes to suit a variety of factory setups.

Introducing our new MH-SERIES Water Wall Dust Collector Series.

Our MH-Series Water Wall Dust Collectors are designed with stonework conditions in mind because it reduces the risk of exposure to crystalline silica by the following methods as recommended by Work Safe (A Health and Safety Solution – Stonemasons – preventing crystalline silica exposure)

- Using wet methods – The MH-Series reduces airborne crystalline silica dust by vacuuming it from the air via a 5-stage wet filtration system.

- By enabling work to be undertaken as close as possible to the extraction point – The MH-Series enables works to be done as close as possible to the extractor. It’s Automatic Energy saving function also means the filtration system will start and stop automatically when you start operating the hand tools. This saves on energy but won’t compromise on effectiveness.

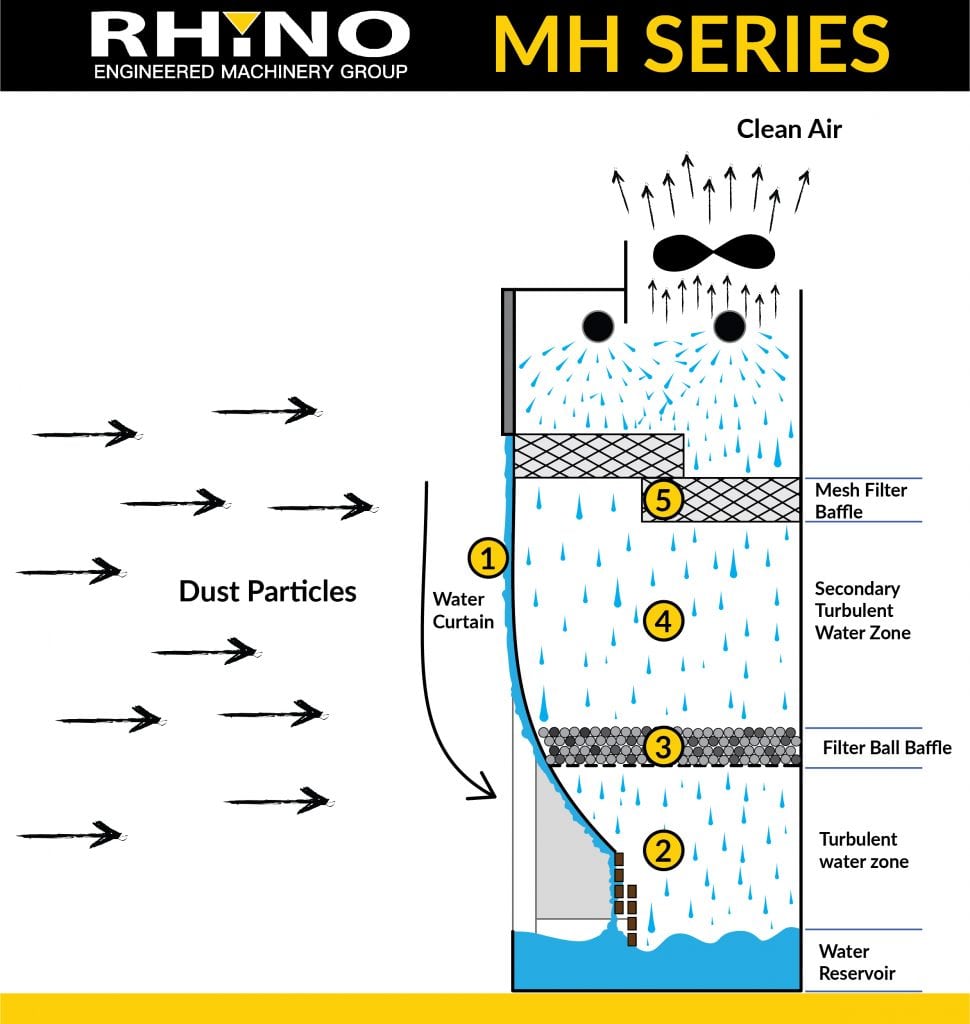

Unique 5 Stage Wet Dust Collection System

Stage 1 Water Curtain.

Dust particles in the air are vacuumed and collected via the water curtain. Further dust particles enter the turbulent water zon.

Stage 2 Turbulent water zone.

Dust particles are collected via immersion within the turbulent water zone.

Stage 3 Filter Ball Baffle.

Further dust particles are collected.

Stage 4 Turbulent water zone.

Further dust particles are collected via immersion within the secondary turbulent water zone.

Stage 5 Mesh Baffle.

Remaining dust particles are collected before clean air is returned to the work environment.

Advantages

-

5 stage dust collection

-

Corrosive resistant

-

Mould resistant

-

Low maintenance

-

Easy to clean

-

Energy saving

Easy to set up, easy to maintain and easily let workers undertake work as close as possible to the extraction point.

Enquire within to see how our MH Dust Collectors can help your business manage your legal health and safety obligations.